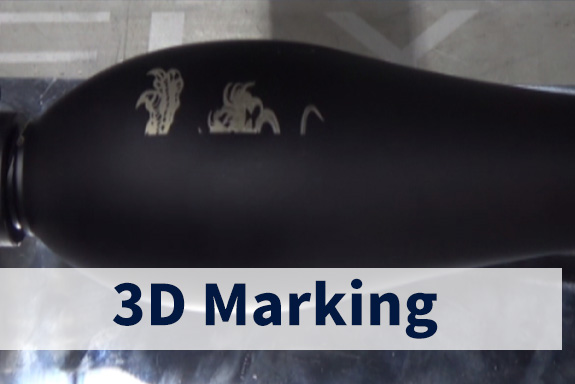

3D Metal Marking with Fiber Lasers

It is an advanced technology that uses a high-energy laser beam to accurately mark the metal surface to achieve three-dimensional shape engraving and marking. The process mainly transmits laser energy through optical fiber, focuses the laser pulse into a very small spot, and controls the laser beam to move precisely on the metal surface through computer control to complete complex 3D graphic engraving. Fiber lasers have the advantages of high power, high stability, and high efficiency. They are suitable for marking various metal materials, including stainless steel, aluminum alloy, copper, titanium, etc. During the 3D metal marking process, the laser interacts with the metal, and the high temperature generated will vaporize or melt the metal surface material to form the desired mark or pattern. This technology is widely used in the fields of automobiles, aerospace, medical devices, electronic components, etc., and is used for parts identification, product traceability, and personalized customization in the manufacturing process.

With the development of Industry 4.0 and intelligent manufacturing, 3D metal marking technology will further promote the upgrading of the manufacturing industry and realize the automation and intelligence of the production process. By integrating the high-precision motion control system of the fiber laser, it is possible to achieve fast and accurate marking of complex three-dimensional models, meeting the needs of modern manufacturing for high-quality and high-efficiency processing technology. In addition, the advantages of fiber lasers in the field of 3D metal marking are also reflected in their flexibility and adaptability. This laser marking technology can easily adapt to various production environments, whether it is a large industrial production line or a small precision laboratory, it can quickly adapt and achieve high-quality marking effects. At the same time, due to the small spot size and extremely high laser energy density of the fiber laser, precise control of tiny details can be achieved, which is especially important for those occasions where tiny feature marking or micro-parts marking is required.

In actual applications, operators only need to set the corresponding parameters through computer programming to achieve flexible control of the fiber laser, so that it can move and mark accurately according to the preset path. This high-precision and high-efficiency marking method greatly improves production efficiency, shortens production cycle, and also reduces production costs and saves resources.

In short, the application of fiber lasers in the field of 3D metal marking not only improves the quality and efficiency of marking, but also promotes the innovation and development of related industries. With the continuous advancement of technology and the expansion of application fields, fiber lasers will play a greater role in the future manufacturing industry.