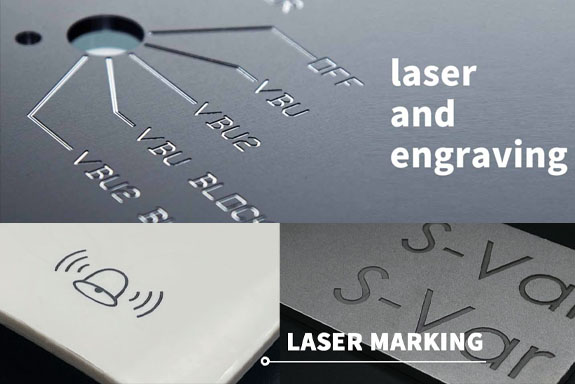

Introduction to Laser Marking on Metals

Laser marking has become an essential technology for marking and engraving metals and other materials across various industries. The development of specialized laser marking equipment, such as fiber laser engravers, MOPA laser engravers, and portable laser markers, has enabled businesses to apply precise, permanent markings on metal tags, PCBs, jewelry, and more. This article explores the applications of laser marking on metals like gold and silver, the technology behind galvo fiber lasers, and the use of handheld and color laser engraving machines for diverse industrial and commercial needs.

Laser Marking on Gold and Silver

Laser marking on precious metals like gold and silver is widely used in jewelry and luxury goods manufacturing, where precision and permanence are critical. Laser marking on gold is often employed for engraving intricate designs, logos, or brand marks, as the laser can create highly detailed marks without damaging the material. Similarly, laser marking on silver enables jewelers and luxury brands to mark items with unique identifiers, quality stamps, or decorative patterns.

The advantage of using laser marking on precious metals is that the process is contactless, preventing scratching or altering the metal’s surface. This is especially beneficial for high-end products, where maintaining material quality and appearance is crucial.

PCB Marking and Identification

PCB marking is a vital application of laser marking in the electronics industry. Printed circuit boards (PCBs) require clear, durable markings to ensure accurate identification and traceability. Laser marking enables manufacturers to place serial numbers, barcodes, and other identifiers on PCBs without affecting their functionality or performance.

Using a galvo fiber laser for PCB marking offers high-speed, precise marking capabilities, which are essential in high-volume production environments. The galvo system allows the laser beam to move quickly over the PCB surface, applying markings with minimal thermal impact on sensitive electronic components.

Metal Tag Engraving Machine for Industrial Applications

Metal tag engraving machines are indispensable in industries where durable labeling is required, such as manufacturing, oil and gas, and logistics. A fiber laser engraver for metal is ideal for creating clear, long-lasting marks on metal tags that can withstand harsh environments. These machines are commonly used to engrave barcodes, serial numbers, and asset information on metal tags for equipment tracking and inventory management.

The laser marking process for metal tags provides excellent readability and resistance to fading, ensuring that critical information remains intact over time. This capability is particularly valuable in industries where assets are exposed to extreme conditions, as laser-marked tags can resist wear and corrosion.

MOPA Laser Engraver for Color Marking on Metal

The MOPA laser engraver is a versatile tool that offers unique capabilities in color laser engraving. By adjusting the laser’s pulse durations, MOPA lasers can produce a range of colors on metals such as stainless steel and titanium. This color laser engraving machine is highly valued in industries where branding and customization are essential, including consumer electronics, luxury goods, and promotional items.

Color laser marking with MOPA lasers allows businesses to create visually distinctive marks without using dyes or chemicals, making it an eco-friendly option. This technology is ideal for applications where product aesthetics are as important as functionality.

Portable and Handheld Laser Marking Machines

Portable laser markers and handheld laser engraving machines offer the convenience of mobility, enabling on-site marking and engraving without the need to transport items to a workstation. This flexibility is invaluable in fields like construction, field engineering, and automotive repair, where parts and equipment may require marking in various locations.

Handheld laser engraving machines are typically powered by fiber marking technology, allowing users to mark metals and some plastics with ease. These devices are particularly useful for marking large or immovable objects, and they are designed to provide high-precision, durable marks even in challenging environments.

Fiber Laser Marking Machine for High-Durability Marking

The fiber marking machine is a staple in industries that require reliable and high-quality marking on metal surfaces. Known for its efficiency and low maintenance, fiber laser marking is used extensively in automotive, aerospace, and electronics manufacturing to mark parts with tracking numbers, logos, and regulatory information.

Fiber lasers are compatible with a wide range of metals, including stainless steel, aluminum, copper, and brass, making them versatile tools for manufacturers. The durability of laser marking achieved with fiber lasers ensures that marks remain readable and intact, even in high-stress environments.

Color Laser Marking Machine for Aesthetic Applications

Color laser marking machines have expanded the creative possibilities for marking and engraving, particularly in industries focused on product branding and customization. These machines use MOPA technology to produce a spectrum of colors on metal surfaces, allowing for highly customizable and visually appealing marks. Color laser marking is popular in industries such as jewelry, fashion, and luxury goods, where brand differentiation and visual impact are crucial.

The ability to create multicolored designs without additional chemicals or inks gives color laser marking machines a unique advantage. This process also enhances the durability of the color, making it resistant to wear and environmental factors.

Applications of Laser Marking Technology Across Industries

Laser marking technology has diverse applications across numerous industries, thanks to its ability to provide precise, high-quality marks on various materials. Here’s a breakdown of some industries that benefit from laser marking:

- Jewelry and Luxury Goods: Laser marking on precious metals like gold and silver enables fine, intricate markings for branding and design.

- Electronics and PCB Manufacturing: Galvo fiber lasers enable rapid and accurate PCB marking, essential for traceability and identification.

- Manufacturing and Logistics: Fiber laser engravers are used for metal tag engraving, providing durable labels for tracking and maintenance.

- Automotive and Aerospace: Laser marking on metal parts ensures compliance with safety and regulatory standards through permanent serial numbers and identification codes.

- Consumer Goods and Promotional Items: Color laser engraving with MOPA lasers allows for custom branding on metal surfaces, enhancing product appeal.

Conclusion

Laser marking has become a cornerstone technology for industries needing high-quality, permanent marking solutions. From MOPA fiber lasers and UV laser marking to portable laser markers and color laser engraving machines, the options available offer unmatched precision, durability, and flexibility. By selecting the right laser marking machine, businesses can improve traceability, brand differentiation, and compliance across various sectors.

由用户投稿整理稿件发布,不代表本站观点及观点,进行交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。