Introduction to 3D Marking

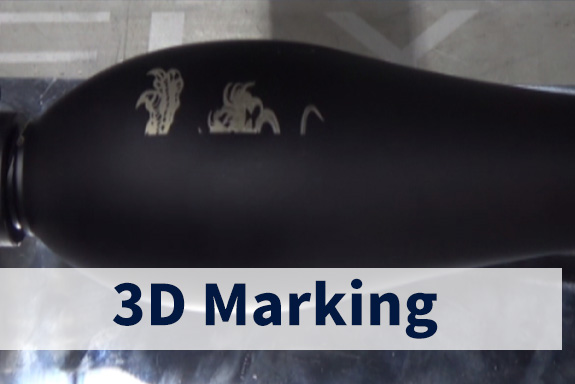

3D marking is an advanced technique that utilizes laser technology to create precise and durable markings on various surfaces. This method is especially popular in industrial applications where traceability and branding are essential. With the integration of a galvano meter, the efficiency and accuracy of 3D marking systems have significantly improved, enabling high-speed operations and intricate designs. As industries adopt 3D marking technologies, the ability to mark on different materials has expanded, making it a versatile solution for many applications.

The Role of Galvano Meters in 3D Marking

Galvano meters play a crucial role in enhancing the capabilities of 3D marking systems. These devices use mirrors to direct the laser beam with high precision, allowing for rapid and accurate marking on surfaces. By incorporating a galvano meter, 3D marking systems can achieve intricate designs on materials such as metals, plastics, and ceramics. The speed and precision offered by galvano meters not only improve productivity but also reduce the risk of errors during the marking process. As a result, industries can maintain high-quality standards while benefiting from efficient 3D marking solutions.

Applications of 3D Laser Scanners

3D laser scanners have revolutionized how we capture and analyze objects in various fields. These devices utilize laser technology to create detailed 3D models of physical objects. In conjunction with 3D marking, scanners can help in accurately identifying the best surfaces for marking. This synergy ensures that the markings are both effective and aesthetically pleasing. 3D marking can be applied to various materials, including metals, glass, and even textiles, making it an ideal choice for manufacturers looking to enhance their branding and traceability efforts.

Advantages of 3D Laser Marking

The advantages of 3D marking are numerous, especially when using advanced technology like laser systems. 3D marking provides permanent markings that are resistant to wear and tear, ensuring that important information remains legible throughout the product’s lifecycle. The flexibility of 3D marking allows for intricate designs, logos, and barcodes to be applied to a wide range of materials, including aluminum, stainless steel, and plastics. This durability makes 3D marking an essential tool for industries such as automotive, aerospace, and consumer goods.

Conclusion

In conclusion, 3D marking, powered by technologies like galvano meters and 3D laser scanners, offers significant benefits across various industries. The ability to create precise, durable, and visually appealing markings on a multitude of materials enhances branding, traceability, and compliance efforts. As technology advances, the adoption of 3D marking solutions will likely grow, providing businesses with the ultimate advantage in product identification and marketing.

由用户整理投稿发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。