Laser welders have become a vital tool in various industries, especially in the field of jewelry making. With their precision and versatility, laser welders are revolutionizing how jewelers handle intricate repairs and customization. This article delves into the factors influencing the price of small laser welding machines, their applications in jewelry, and the specific benefits of using a laser welder for jewelry.

Understanding Laser Welders

A laser welder is a sophisticated tool that uses a focused laser beam to join materials together. The laser’s high energy melts the metal at precise points, allowing for the creation of strong, clean welds with minimal thermal distortion. Laser welding technology is particularly valuable in jewelry making due to its ability to work with delicate and intricate designs.

Small Laser Welding Machine Price

When considering a small laser welding machine, the price is an important factor to evaluate. Small laser welders, designed for precision tasks like jewelry repairs, can vary widely in cost depending on several features:

- Power Output: The power of the laser, typically measured in watts, impacts the machine’s ability to handle different materials and thicknesses. Small laser welders for jewelry often range from 20W to 100W. Higher power machines can handle more demanding tasks but come at a higher cost.

- Precision and Features: Advanced features such as programmable settings, autofocus, and high-resolution optics can increase the price. For jewelry work, precision is crucial, so investing in a machine with fine control capabilities is essential.

- Brand and Quality: Reputable brands known for their reliability and support tend to have higher prices. However, they often offer better build quality and longer warranty periods.

- Additional Accessories: Some machines come with additional accessories like microscopes, foot pedals, and cooling systems, which can also affect the overall price.

Small laser welding machines for jewelry can range from approximately $5,000 to over $20,000, depending on these factors. It is important to balance cost with the specific needs of your jewelry business to ensure you invest in a machine that offers the best value and performance.

Jewelry Laser Welder Applications

Jewelry laser welders are specifically designed to meet the unique needs of jewelry making. Here’s how a laser welder benefits various aspects of jewelry work:

Precision Repairs

One of the main advantages of a jewelry laser welder is its precision. The laser beam can be finely controlled, allowing jewelers to perform detailed repairs on intricate pieces. Whether fixing a broken prong, reattaching a stone, or addressing small cracks, a laser welder ensures that repairs are done with minimal impact on the surrounding areas.

Customization and Design

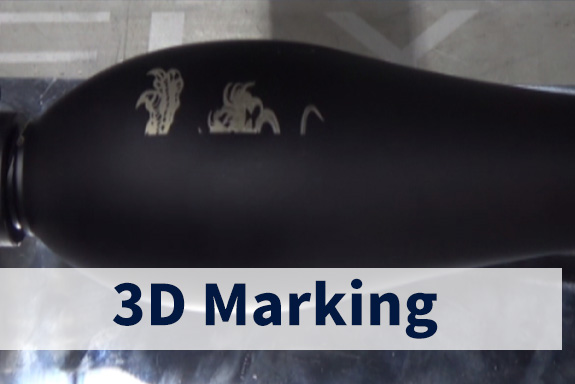

Laser welders also excel in customization and design work. Jewelers can use these machines to add custom engravings, set stones, or create intricate patterns that would be challenging with traditional welding methods. The high precision of a laser welder allows for complex designs to be executed with high accuracy and minimal distortion.

Joining Different Metals

Jewelry often involves joining different types of metals, such as gold, silver, and platinum. A laser welder can handle these materials with ease, providing strong and clean welds. The ability to weld different metals without affecting the properties of the surrounding areas is a significant advantage for creating high-quality jewelry.

Advantages of Using a Laser Welder for Jewelry

Minimal Heat Affected Zone

Laser welding creates a minimal heat-affected zone (HAZ), which means less thermal distortion and a smaller area affected by heat. This is particularly important in jewelry making, where the surrounding material needs to remain pristine and undamaged.

Precision and Control

The precise control offered by a laser welder allows for detailed and accurate welding. This is crucial for working with small components and delicate designs in jewelry, where even the slightest error can affect the final product.

Reduced Post-Weld Cleanup

Due to the precision of laser welding, there is often less need for post-weld cleanup. The clean welds produced by a laser welder reduce the need for additional finishing work, which saves time and improves overall productivity.

Versatility

Laser welders are versatile tools that can handle a variety of tasks beyond jewelry repair, such as creating custom designs and joining different metals. This versatility makes them a valuable addition to any jewelry workshop.

Choosing the Right Jewelry Laser Welder

When selecting a jewelry laser welder, consider the following factors to ensure you choose the best machine for your needs:

- Power and Performance: Ensure the machine has adequate power for the types of welding you need. For intricate jewelry work, precision and control are more important than sheer power.

- Features and Accessories: Look for features that enhance functionality, such as adjustable settings, high-resolution optics, and ergonomic controls. Accessories like microscopes can also aid in precision work.

- Brand and Support: Choose a reputable brand with good customer support and service options. This ensures that you have access to assistance and maintenance when needed.

- Budget: Balance your budget with the features and capabilities you require. While higher-priced machines may offer more advanced features, ensure they align with your specific needs.

Conclusion

Laser welders are transformative tools in the jewelry industry, offering precision, versatility, and efficiency. Understanding the factors influencing the price of small laser welding machines, including power output and additional features, is crucial for making an informed investment. With their ability to handle intricate repairs, customization, and metal joining, jewelry laser welders provide exceptional value for jewelers looking to enhance their craftsmanship and efficiency. By selecting the right laser welder for your needs, you can achieve high-quality results and maintain the integrity of your jewelry creations.

由用户整理投稿发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。