Versatility of laser marking technology

Laser marking technology has revolutionized the way products are marked and identified across industries. This advanced marking and engraving method provides unparalleled accuracy and durability, making it a popular choice for a variety of applications. From industrial manufacturing to medical devices and consumer electronics, laser marking has become an indispensable tool for creating permanent, high-quality marks on a variety of materials. In this article, we will explore the diverse applications of laser marking technology and their impact on different industries.

Industrial applications of laser marking

In the industrial field, laser marking has been widely used to mark and engrave various components and products. One of the main advantages of laser marking is the ability to create high-contrast, permanent marks on metals, plastics, ceramics, and other materials. This makes it ideal for applications such as part identification, serial numbers, barcoding and branding. Additionally, laser marking machines are capable of producing complex designs and fine details, making them suitable for marking small parts and complex patterns.

The automotive industry, in particular, has adopted laser marking to mark parts and components with serial numbers, logos and other important information. This ensures traceability and quality control throughout the manufacturing and assembly process. Likewise, in the aerospace and defense sector, laser marking is used to mark critical components, tools and equipment with unique identifiers and part numbers, thereby enhancing safety and complying with industry regulations.

Medical and pharmaceutical applications of laser marking

In the medical and pharmaceutical industries, the need for precise, permanent marking on instruments, implants and packaging has led to the widespread adoption of laser marking technology. Medical devices and equipment often require unique identification numbers, lot numbers and other basic information for tracking and regulatory purposes. Laser marking machines provide a non-contact, high-precision method of marking surgical instruments, orthopedic implants and other medical devices with intricate details and alphanumeric codes.

In addition, laser marking can be used to mark batch numbers, expiration dates and product information on pharmaceutical packaging such as blister packs, vials and syringes. Laser marking has the ability to create tamper-evident and anti-counterfeiting features on pharmaceutical packaging, adding an extra layer of security and authenticity to products, preventing counterfeit medicines and ensuring patient safety.

Consumer electronics and personalized products

Laser marking technology has also made significant progress in the consumer electronics and personalized product markets. From smartphones and laptops to electronics and accessories, laser marking can be used to add logos, serial numbers and regulatory markings to electronic components and devices. The high precision and non-invasive nature of laser marking make it ideal for marking precision electronic components without causing damage or deformation.

Additionally, the trend toward customization and personalization of consumer products has led to the use of laser marking to create personalized engravings on items such as jewelry, watches, and personal accessories. Whether it’s a custom message, decorative pattern, or company logo, laser marking machines have the flexibility to create complex and durable marks on a variety of materials, including metal, plastic, and even organic materials like wood and leather.

Progress in laser marking technology

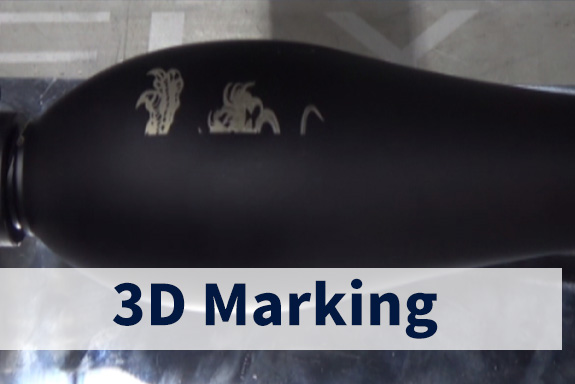

Continuous advancements in laser marking technology have expanded its capabilities and applications in various industries. The introduction of fiber lasers has significantly improved the speed and efficiency of laser marking, especially for marking metals and high-contrast materials. Fiber lasers produce clear, high-resolution marks at faster speeds, making them ideal for high-volume production environments.

In addition, the integration of automation and computer-aided design (CAD) software with laser marking machines enables seamless marking of complex designs, variable data and 2D codes. This opens up new possibilities for product customization, serialization and traceability, especially in industries where personalized marking and unique identifiers are critical for quality control and supply chain management.

To sum up, laser marking technology is widely used and has far-reaching influence, spanning the automotive, medical, consumer electronics and other industries. The precision, durability and versatility of laser marking make it an indispensable tool for creating high-quality marks on a variety of materials, helping to improve traceability, product identification and brand recognition. As technology continues to evolve, the potential for laser marking to further enhance the product marking and identification process is limitless, driving innovation and efficiency in various fields.

由用户整理投稿发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。