Introduction to UV Laser Engraving and UV Laser Marking

UV laser engraving and UV laser marking are advanced laser technologies used for high-precision marking, engraving, and etching on a variety of materials. Unlike other laser technologies that use infrared or visible light, UV lasers operate in the ultraviolet spectrum, typically at wavelengths of 355 nm, allowing them to produce cleaner, more precise marks with minimal heat impact.

In this article, we will explore how UV laser engraving and UV laser marking work, their advantages, and how they compare to other laser technologies. We will also delve into the role of 20w fiber laser systems, portable laser engraving machines, and the laser marking machine price range, helping businesses and individuals make informed decisions when purchasing these technologies.

UV Laser Engraving: A Superior Solution for Precision and Detail

UV laser engraving utilizes a UV laser, typically with a wavelength of around 355 nm, to remove material from the surface of an object. This technology is particularly useful for applications requiring intricate and precise designs on a variety of materials, including plastics, glass, ceramics, and even certain metals. The high-precision capabilities of UV laser engraving make it ideal for industries such as electronics, medical devices, packaging, and more.

Key Benefits of UV Laser Engraving:

- High Precision: The short wavelength of UV lasers enables extremely fine detail, which is critical for applications such as engraving small logos, serial numbers, and barcodes.

- Minimal Heat Impact: One of the most significant advantages of UV laser engraving is the reduced thermal effect on the material being marked. This ensures that materials like plastics and glass do not warp, melt, or discolor during the engraving process.

- Wide Material Compatibility: UV lasers work effectively on a wide range of materials, including both organic (plastics, wood) and inorganic (metals, ceramics) substrates.

Applications of UV laser engraving include:

- Engraving logos and serial numbers on medical devices and components.

- Marking or etching information on packaging materials like glass bottles.

- Creating intricate designs on jewelry or consumer electronics.

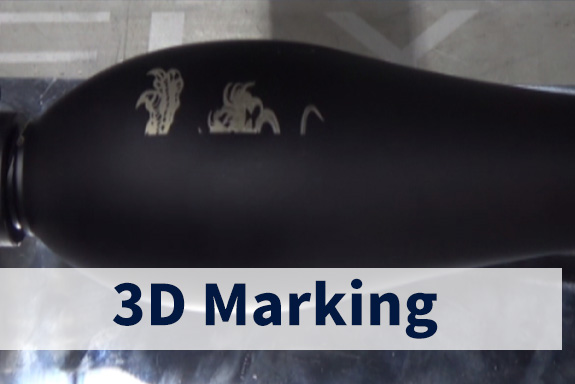

UV Laser Marking: Fast, Efficient, and Clean Marking

UV laser marking is similar to UV laser engraving, but rather than removing material from the surface, it uses the UV laser to modify the surface of the material to create high-contrast marks. This process is typically used for creating permanent, readable markings such as logos, text, barcodes, and QR codes, without compromising the integrity of the material.

Advantages of UV Laser Marking:

- Clean and Precise Marks: UV laser marking provides high-contrast, clean marks without the need for inks or consumables, reducing the environmental impact.

- Minimal Heat Impact: Like engraving, UV laser marking does not involve excessive heat, making it ideal for delicate materials like thin plastics, acrylics, or coated metals.

- Durability: UV laser markings are resistant to wear and tear, making them permanent even under harsh environmental conditions.

Industries that benefit from UV laser marking include:

- Electronics (e.g., marking circuit boards and semiconductors).

- Medical devices (e.g., engraving patient information on surgical instruments).

- Packaging (e.g., marking expiration dates or logos on products).

20w Fiber Laser: A Versatile Solution for Engraving and Marking

The 20w fiber laser is a versatile laser technology commonly used for engraving and marking a variety of materials, especially metals, plastics, and ceramics. Compared to UV lasers, fiber lasers generally operate at wavelengths in the near-infrared spectrum (usually around 1064 nm), which gives them a different set of advantages.

Key Advantages of 20w Fiber Laser:

- High Power for Metal Marking: 20w fiber lasers are particularly effective for marking and engraving metals, such as steel, aluminum, and titanium, thanks to their ability to generate higher power densities.

- Faster Processing Speed: With higher power output, fiber lasers can process materials faster than UV lasers, making them ideal for high-volume production environments.

- Durability and Low Maintenance: Fiber lasers are more durable and have a longer lifespan than traditional CO2 lasers, leading to reduced maintenance costs.

Applications of 20w Fiber Laser:

- Metal Engraving: Marking metal parts with serial numbers, logos, and barcodes.

- Plastic Engraving: Engraving designs on plastics, such as automotive components or consumer electronics.

- Industrial Marking: Used in automotive, aerospace, and manufacturing industries for durable and precise marking.

While UV lasers offer advantages in terms of precision and heat management, 20w fiber lasers excel in speed and power, making them suitable for different marking and engraving tasks.

Portable Laser Engraving Machine: Flexibility and Convenience for On-the-Go Marking

For businesses or individuals needing a more flexible solution, portable laser engraving machines provide a compact and mobile option. These machines are often equipped with fiber lasers and can be used for engraving or marking a wide variety of materials in different settings, including workshops, factories, or on-site at client locations.

Benefits of Portable Laser Engraving Machines:

- Mobility: The ability to transport a laser engraving machine to different locations is ideal for businesses that provide on-site services or need to engrave items that are too large to transport easily.

- Cost-Effective: Portable laser engraving machines are typically more affordable than larger, industrial models while still offering high-quality marking and engraving capabilities.

- Ease of Use: Many portable machines come with user-friendly interfaces and simple setup processes, making them accessible even for users with limited experience in laser technology.

Applications of portable laser engraving machines include:

- Personalized Gifts: Engraving custom designs or names on items like jewelry, trophies, or glassware.

- On-Site Industrial Marking: Marking or engraving parts directly at a manufacturing site or factory.

- Product Customization: Customizing products like phone cases, tools, and promotional items.

Understanding Laser Marking Machine Price Range

When considering the purchase of a laser marking machine, it is important to factor in the price, which can vary significantly depending on the technology, power, and features of the machine. For instance, UV laser marking machines typically tend to be more expensive than fiber laser marking machines due to the specialized technology they use.

Price Factors for Laser Marking Machines:

- Technology Type: UV laser marking machines are generally more expensive than fiber or CO2 laser machines.

- Power: Higher-powered lasers, such as 20w fiber lasers or CO2 lasers, tend to cost more due to their increased performance capabilities.

- Brand and Features: Renowned brands or machines with advanced features, such as automation capabilities, larger work areas, or higher processing speeds, can also add to the price.

On average, laser marking machines can range from a few thousand dollars for lower-power fiber laser machines to tens of thousands of dollars for high-end UV laser engraving systems. It’s important to consider the long-term return on investment based on the volume of production and the precision requirements for your specific applications.

Conclusion: Choosing the Right Laser Technology

Whether you’re looking for a UV laser engraver, a fiber laser marking system, or a portable laser engraving machine, each type of laser has its distinct advantages and is suited to different applications. UV laser engraving provides high precision with minimal thermal impact, ideal for delicate materials, while 20w fiber lasers are more versatile for marking and engraving metals and plastics.

When choosing a laser marking machine, it’s essential to consider the material types you will work with, the level of detail required, and the laser marking machine price to ensure the best fit for your business or personal needs.

Company Introduction

Beijing JCZ Technology Co., Ltd. (Stock Code: 688291) was established in 2004 and focuses on the research and development of control software, systems, and components in the field of laser industrial processing. It is recognized by the Ministry of Industry and Information Technology as a specialized and innovative “The Rising Star Award” enterprise, a specialized and innovative “The Rising Star Award” enterprise in Beijing, a high-tech enterprise recognized by the Beijing Municipal Science and Technology Commission, and a partner unit in Fengtai District’s “Doubling Catch-up and Cooperative Development” initiative.

In the future, JCZ will continue to innovate technologically and strive to build a “Beam Delivery & Control” technology platform, providing customers with “Integrated Drive and Control” products and comprehensive solutions, delivering high-quality products and services to system integrators and users, and becoming a competitive and influential “Beam Delivery & Control Expert.”

由用户投稿整理稿件发布,不代表本站观点及观点,进行交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。