Laser cleaning machines have revolutionized the way industries handle rust, paint, and surface contaminants by providing an efficient, precise, and eco-friendly alternative to traditional cleaning methods. However, choosing the right laser cleaning machine can be challenging given the range of options available. Here’s a guide to help you make an informed decision.

Understand the Type of Contaminant

Different laser cleaning machines are suitable for various types of contaminants. Commonly, laser cleaning is used to remove rust, paint, grease, and oxides from surfaces. However, you’ll need to understand the specific contaminant on the material you are cleaning. Some contaminants, such as oil, might require a laser with lower power settings, while tough materials like rust need higher power. Make sure the machine you select is capable of effectively handling the contaminants you’re dealing with.

Consider the Power Level

Laser cleaning machines come in a range of power levels, typically from 20 watts to 1,000 watts or more. Higher power allows for faster cleaning but might also damage delicate surfaces. Lower-power machines are slower but safer for sensitive materials. If you need high-speed cleaning for large industrial applications, consider a high-power laser cleaning machine. However, if precision and surface integrity are essential, a lower-power machine might be ideal. Think about both your cleaning speed requirements and the surface materials to select the appropriate power level.

Evaluate the Cleaning Speed

The speed at which a laser cleaning machine can remove contaminants is essential, especially for industrial applications where efficiency is crucial. High-speed machines are more suited for large areas and heavy-duty cleaning. However, higher speed typically correlates with higher power and cost. If you are working with small or intricate components, a slower machine with more precision may be preferable. Balance the need for speed with the precision requirements of your project to choose the best option.

Assess the Laser Wavelength

Laser cleaning machines operate at different wavelengths, typically in the range of nanometers (nm). Wavelength is a critical factor because certain wavelengths are better suited for specific materials. For example, 1064 nm lasers are effective for metals, while other wavelengths might work better on non-metals. When choosing a laser cleaning machine, consult the specifications to ensure the wavelength matches your material. Choosing the correct wavelength ensures that you’ll achieve efficient cleaning without damaging the underlying surface.

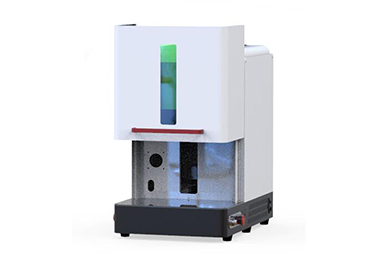

Portability and Machine Design

Consider whether a portable or stationary machine best suits your needs. Portable laser cleaning machines are ideal for fieldwork and remote cleaning tasks, while stationary units are better suited for a fixed workshop environment. Additionally, look for machines with ergonomic designs and user-friendly interfaces, as this can make a difference in long-term usability. Some portable models come with wheeled systems for easier mobility, while larger, stationary machines may require dedicated space in a facility.

Safety Features

Safety should be a priority when working with laser equipment. Look for laser cleaning machines with built-in safety features, such as enclosed systems, emergency stop buttons, and laser protective shielding. Additionally, machines with automatic power-off functions add an extra layer of security, especially in industrial settings where users might interact with heavy machinery. Ensure that the machine you choose meets international safety standards to protect operators during use.

Budget and Cost-Effectiveness

Laser cleaning machines vary significantly in price depending on power, brand, and additional features. While budget considerations are essential, try not to compromise on essential features like power and safety. It’s often more cost-effective to invest in a slightly higher-priced machine with durable, high-quality components. Compare options from different manufacturers to find a machine that offers the best balance between cost and functionality.

Consider the Manufacturer’s Reputation

A reliable manufacturer is crucial when choosing a laser cleaning machine. Check reviews, ask for client testimonials, and research the manufacturer’s reputation in the industry. A reputable supplier is likely to offer better quality machines, reliable customer support, and long-term maintenance. Additionally, some manufacturers offer training and technical assistance, which can be invaluable for new users.

After-Sales Service and Warranty

Before finalizing your purchase, check the warranty terms and after-sales service options. Machines used in industrial applications may require maintenance and repairs, so choose a supplier who offers comprehensive support. Some suppliers provide service packages that include routine inspections, while others offer extended warranties for an additional fee. Reliable after-sales service ensures that your laser cleaning machine remains operational for years to come.

Final Thoughts

Selecting the right laser cleaning machine involves considering various factors, including contaminant type, power level, speed, wavelength, portability, and safety. By thoroughly evaluating each of these areas, you can choose a machine that matches your needs and budget. For additional guidance or specific inquiries, contact us or consult with a trusted supplier to find the ideal laser cleaning machine for your application.