Introduction to Laser and Engraving

Laser and engraving technologies have transformed the way industries approach marking and personalization. Utilizing a laser machine for marking allows for high precision and speed, making it an essential tool in various sectors. From intricate designs on jewelry to identification marks on industrial components, laser engraving offers unparalleled detail and accuracy. This technology has become increasingly accessible, leading to the widespread adoption of laser engraving equipment across different markets.

One of the primary advantages of using a laser machine for marking is its versatility. Unlike traditional engraving methods, which can be limited to specific materials, laser and engraving processes can be applied to a wide range of surfaces, including metals, plastics, and wood. This flexibility enables businesses to meet diverse customer demands while maintaining high-quality results.

Types of Laser Engraving Equipment

When considering laser and engraving solutions, it’s essential to understand the different types of laser engraving equipment available. Each type serves unique applications and materials, making the choice of a laser machine for marking crucial for achieving the desired outcome. For example, fiber laser engravers are particularly effective for marking metals, offering superior speed and precision compared to other laser types.

Fiber laser engravers utilize a solid-state laser source, making them efficient for engraving hard materials like stainless steel and aluminum. This technology is perfect for industries requiring durable and long-lasting markings. By leveraging the capabilities of a fiber laser engraver, companies can ensure that their products carry clear, permanent marks that withstand harsh conditions.

Applications of Laser and Engraving Technologies

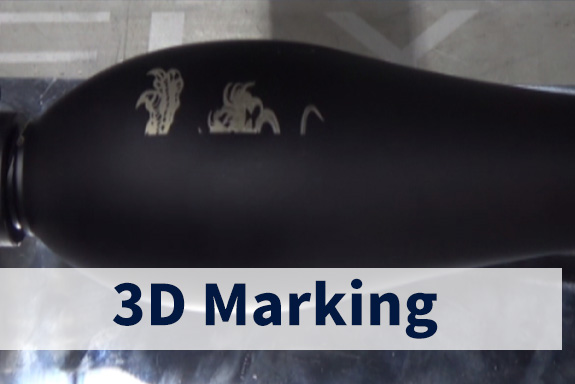

Laser and engraving technologies find applications in various industries, from manufacturing to marketing. The ability to use a laser machine for marking makes it an ideal choice for branding and product identification. Companies can engrave logos, serial numbers, and barcodes directly onto their products, enhancing traceability and brand recognition.

Additionally, the personalization potential of laser engraving is immense. Businesses can offer customized items, such as engraved gifts or promotional materials, appealing to customers’ desires for unique products. This aspect of laser and engraving allows companies to differentiate themselves in competitive markets, driving customer loyalty and satisfaction.

The Advantages of Using Laser Machines for Marking

The benefits of using laser and engraving technology are numerous. A laser machine for marking provides a clean, precise finish without the risk of damage to the material. Unlike traditional engraving methods that can produce burrs or rough edges, laser engraving results in smooth and polished surfaces. This quality is especially important in industries where aesthetics and functionality go hand in hand.

Moreover, laser and engraving systems are highly efficient. They can operate continuously without wear and tear, leading to lower operational costs over time. This efficiency, combined with the ability to quickly change designs or settings, makes laser engraving equipment a valuable asset for businesses looking to streamline their operations.

Choosing the Right Laser Engraving Equipment

Selecting the right laser engraving equipment involves considering various factors, including the intended application and materials. A laser machine for marking should match the specific requirements of the business. For example, if a company primarily works with metals, investing in a fiber laser engraver would be the best option to ensure optimal results.

It’s also crucial to evaluate the features of the engraving equipment. Modern laser machines often come with advanced software that enables precise control over engraving depth, speed, and patterns. These features allow businesses to maximize their productivity and produce high-quality engravings that meet customer expectations.

Future Trends in Laser and Engraving Technologies

The future of laser and engraving technologies looks promising, with ongoing advancements pushing the boundaries of what’s possible. As laser machines for marking become more sophisticated, we can expect enhanced capabilities in terms of speed, precision, and material compatibility. Innovations like AI-driven engraving systems may also emerge, enabling even greater customization and efficiency.

Additionally, the integration of laser and engraving technologies with smart manufacturing systems will likely transform production processes. By incorporating automation and real-time monitoring, businesses can optimize their workflows, reduce waste, and enhance overall quality. These advancements will position laser engraving as an essential component of future manufacturing strategies.

Conclusion

In conclusion, laser and engraving technologies represent a significant leap in marking solutions for various industries. The versatility of a laser machine for marking, combined with the precision of laser engraving equipment, has made it a go-to choice for businesses seeking high-quality results. As the technology continues to evolve, the applications and benefits of laser engraving will only expand, solidifying its role in modern manufacturing and personalization.

由用户整理投稿发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。