In the industrial manufacturing and maintenance sectors, the need for efficient and effective surface treatment solutions is critical. Whether removing old coatings, cleaning metal surfaces, or removing rust and oxide layers, traditional methods often fall short in terms of precision, speed and environmental impact. However, the advent of laser technology has led to a game-changing solution, namely laser coating removal cleaning machines. These cutting-edge devices are revolutionizing the surface treatment process, offering a range of benefits that are reshaping the way the industry meets its surface treatment needs.

Learn about laser coating removal

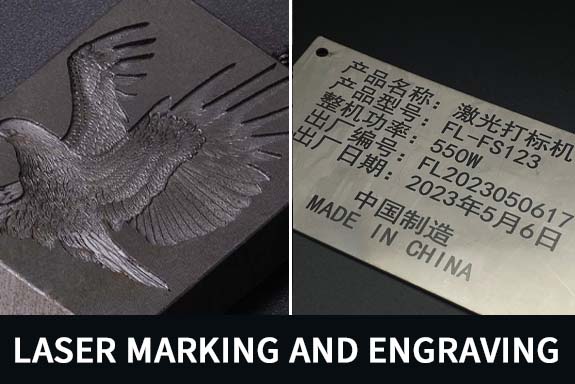

Laser coating removal, also known as laser ablation coating removal, involves the use of high-energy laser beams to selectively remove coatings, paint, rust, and oxide layers from a variety of surfaces. Unlike traditional methods such as sandblasting, chemical stripping or abrasive grinding, laser coating removal offers a non-contact, precise and environmentally friendly method of surface treatment. This process is particularly effective on delicate or complex surfaces where traditional methods may cause damage or require extensive physical labor.

The technology behind laser coating removal cleaning machines

Laser coating removal cleaning machines are equipped with advanced laser systems that emit high-intensity light pulses. These pulses are precisely controlled to target and evaporate unwanted coatings or contaminants on the surface, leaving the substrate intact. These machines are designed to work with a variety of materials, including metals, plastics, composites, and more, making them versatile tools for a variety of industrial applications.

Advantages of Laser Coating Removal Cleaning Machine

The adoption of laser coating removal cleaning machines brings many benefits to industries looking for efficient, sustainable surface treatment solutions. Some key advantages include:

- Precise: Laser technology allows precise control of the removal process, ensuring that only targeted coatings or contaminants are affected while maintaining the integrity of the underlying material.

- Speed: The laser coating removal cleaning machine can operate at high speed, which greatly reduces the time required for surface treatment compared with traditional methods.

- Environmentally Friendly: Unlike chemical-based stripping processes, laser coating removal is a clean and environmentally friendly method that produces minimal waste and eliminates the need for the use of harmful chemicals.

- Versatility: These machines can be customized to accommodate different surface materials and coatings, making them suitable for a wide range of industrial applications.

- Cost-Effectiveness: While the initial investment in a laser coating removal cleaning machine may be higher than traditional equipment, the long-term cost savings in reduced labor, material waste, and environmental compliance can be significant.

Application of laser coating removal cleaning machine

The versatility and effectiveness of laser coating removal cleaning machines make them an indispensable tool in various industries. Some common applications include:

- Aerospace: The aerospace industry relies on precise surface treatment of components, and laser coating removal cleaning machines provide a non-destructive method for maintaining and refurbishing aircraft components.

- Automotive: From removing old paint and coatings to cleaning metal surfaces, laser coating removal is widely used in automotive manufacturing and restoration processes.

- Marine and Offshore: The marine and offshore industry benefits from the ability of laser coating removal cleaning machines to remove rust and corrosion from metal surfaces, thereby extending the life of critical infrastructure and equipment.

- Electronics: Laser coating removal is used in the electronics industry for selective cleaning and refurbishment of precision components without causing damage.

- Cultural Heritage Protection: In the protection of historical artifacts and monuments, laser coating removal offers a gentle yet effective method of removing unwanted layers without compromising the integrity of the underlying material.

Future Developments and Considerations

As technology continues to advance, the capabilities of laser coating removal cleaning machines are expected to further develop. Ongoing research and development efforts focus on improving the efficiency, precision and adaptability of these machines to meet the changing needs of various industries. Additionally, as adoption of laser coating removal technology continues to grow, considerations around safety, operator training and regulatory compliance remain critical.

In summary, laser coating removal cleaning machines represent a significant advancement in surface treatment technology, offering a combination of precision, speed and environmental sustainability unmatched by traditional methods. As industries continue to prioritize efficiency and sustainability, adoption of these innovative machines will become increasingly widespread, reshaping the surface treatment landscape across different industries.