Laser marking machines are used to permanently mark text, logos, barcodes or 2D codes on parts in all industries. Common types of marking include oxidizing, annealing, engraving, etching, discoloration and machining.

Laser Marking Machine

Marking Materials

The Laser Marking & Engraving Machine is designed for high-precision marking on various materials. It is ideal for metal marking, ensuring clear and permanent engravings on stainless steel, aluminum, and other alloys. It also excels in ceramic marking, creating detailed patterns without damaging the surface. For plastic marking, it delivers high-contrast results on ABS, PVC, and other synthetic materials. Additionally, it is suitable for wood marking, producing sharp and durable engravings on hardwood and plywood. The machine also supports glass marking, offering precise frosted effects, and rubber marking, ensuring long-lasting identification on industrial rubber parts.

Marking Applications

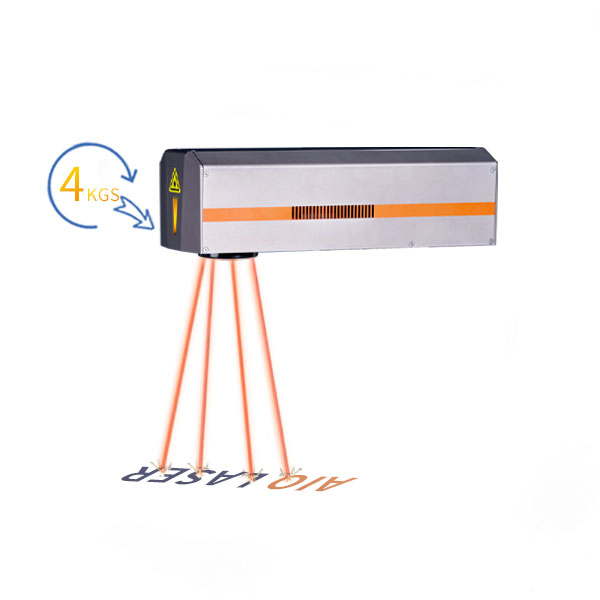

Laser technology offers a wide range of marking and processing capabilities, catering to various industrial and creative applications. From laser marking, laser engraving, and laser etching, which provide permanent and high-contrast markings, to laser annealing and laser labeling, which offer precise and durable identification, the possibilities are extensive. Advanced processes like laser cleaning, laser rust removal, and laser oxide removal efficiently restore surfaces without damaging the base material. Techniques such as laser ablation, laser texturing, and laser paint removal further expand the scope of surface treatment. Additionally, specialized functions like black and white marking, rotary marking, deep engraving, large-format marking, curved surface marking, on-the-fly marking, and camera-assisted marking ensure adaptability for different shapes, sizes, and production requirements. Whether for precision manufacturing or high-speed production lines, laser technology remains a versatile and indispensable tool.

Suitable Industries

Laser marking machines are widely used across various industries due to their precision, durability, and versatility. In the automotive sector, they are used for marking serial numbers, barcodes, and part identification. The semiconductor industry relies on laser marking for wafer marking and microchip labeling. In food and pharmaceutical industries, laser marking ensures traceability and compliance by marking expiration dates, batch numbers, and QR codes. Electric vehicle (EV) manufacturers use laser marking for battery components and electronic parts. In medical applications, lasers mark surgical tools and medical implants with high precision. The agriculture and farming industry uses laser technology for labeling equipment and tools. Battery manufacturers utilize laser marking for safety labeling and traceability. Lastly, in the aerospace sector, laser marking ensures long-lasting identification of aircraft components under extreme conditions.

Laser Marking Machine

Laser marking machines use high-energy light to mark the surface of a part. Laser markers vary by wavelength of light, with different wavelengths optimized for marking and processing different materials. Laser marking machines have permanent markings and are compatible with a wide range of materials. The marks made by these machines are very reliable as they are difficult to be damaged by conditions and substances such as oil, steam, emulsions and high temperatures.

Advantages of laser engraving machines

Permanent marking

Marks left by inkjet and pad printing systems are temporary and may rub off or fade. Laser marking does not abrade or contaminate the product being marked.

Zero consumables

Because laser markers use light to directly mark products, there is no need to purchase consumables, clean print heads or perform other routine maintenance tasks required by traditional ink and label marking methods. This also helps to reduce associated maintenance costs.

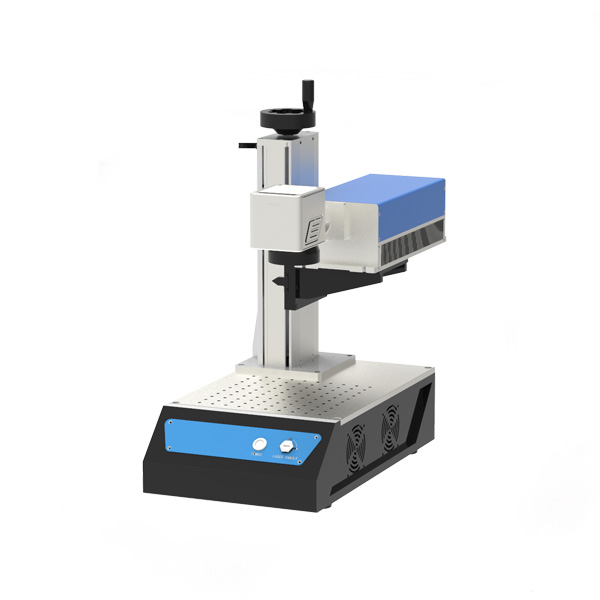

3-Axis Marking

Typical systems can only mark in 2 dimensions (X and Y.) The JCZ Laser Marker features 3-axis beam control, making it possible to mark over larger areas, compensate for part variations, and correct for mounting limitations without having to make any physical equipment adjustments.

Resistant to Shot Peening Impact

For industries that use shot peening to strengthen parts, laser markers can be the solution to ensure that markings are shot peening resistant. Laser marking machines use engraving to create 2D codes that do not completely lose their luster due to shot peening.

List of materials compatible with laser marking systems:

Wood

Plastic

Glass

Ceramic

Rubber

Different types of marking machines

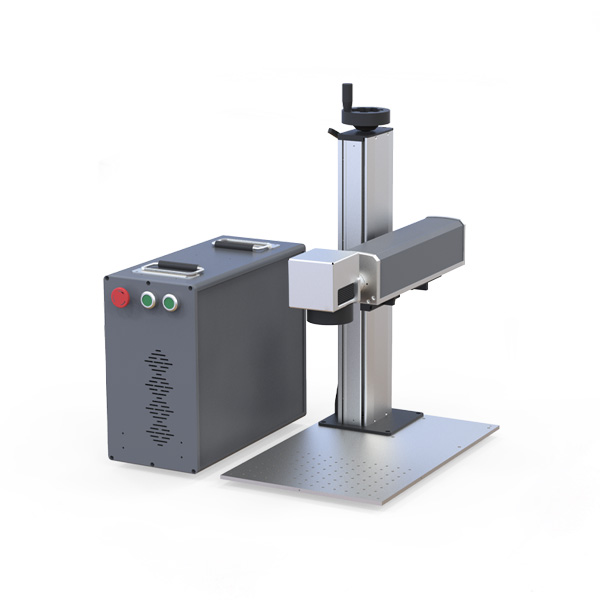

Fiber laser marking machine (1064 nm wavelength)

Fiber laser markers are the latest development in laser marking systems, using low-maintenance solid-state laser sources. They have an efficient cooling system. Therefore, they are very popular among existing laser marking systems. In addition, they do not require material consumption; these fiber laser markers are ideal for marking metals such as stainless steel, aluminum and some plastics.

CO2 laser markers (wavelength 1.06 µm)

CO2 laser markers use a mixture of excited carbon dioxide gas and are ideal for a wide range of industries looking for high efficiency and excellent laser beam quality.CO2 laser marking tools are suitable for marking non-metallic materials and most plastics. In addition, they can mark a variety of different man-made and natural substances.

Below is a list of materials that are compatible with CO2 laser marking systems:

Wood

Acrylic fiber

Glass

Paper

Textiles

Rubber

Plastic

Foil and film

Leather

Stone

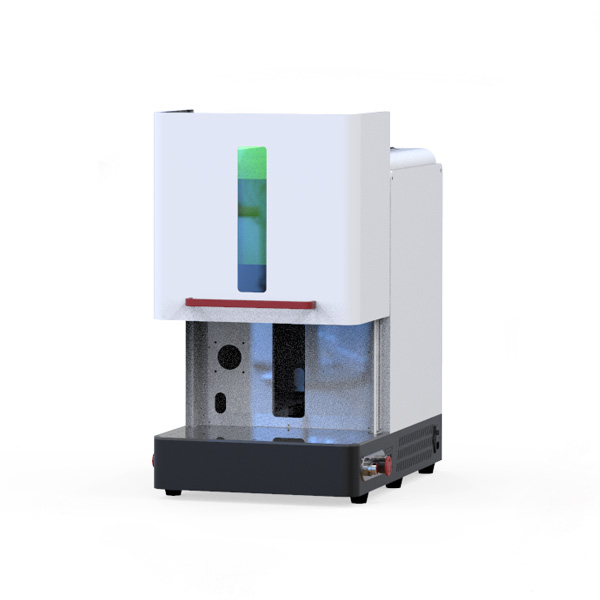

UV laser markers (0.355 µm wavelength)

UV laser markers use ultraviolet light to break the bonding bonds on the surface of the material to be marked. This is a cold process that does not produce peripheral heating; hence, UV laser markers are called cold lasers. Because of the cold process, UV lasers do not pose any risk to the strength or thermal integrity of the target material, making them the perfect laser engraver or laser etcher for fine materials such as plastics and thin latex.

UV laser systems can work at very high speeds and are used to mark semiconductors and plastics (e.g. PVC, ABS, polypropylene), metals, paper and ceramic chips.