Fiber laser welding machines provide non-contact, high-speed metal welding solutions for advanced manufacturing by melting metal to produce high-quality welds.

Laser Welding Machine

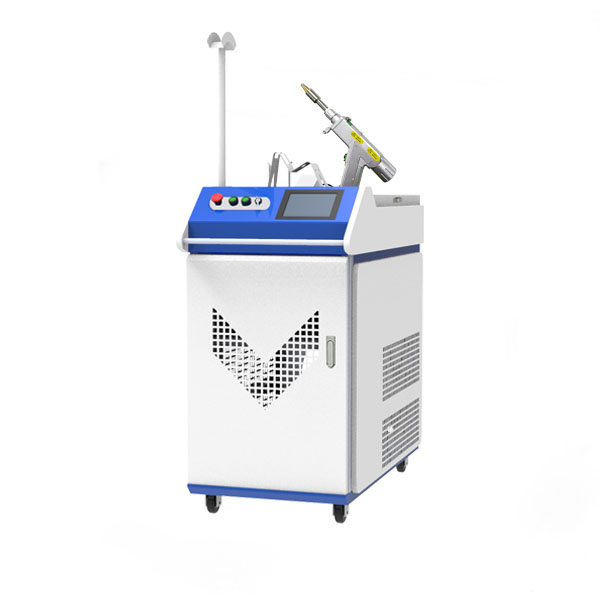

Fiber Laser Welding Machine

Laser welding is a process that uses a laser beam to join metals or thermoplastics together to form a weld. Since the laser is a concentrated heat source, it is able to weld thin materials at high speeds of a few meters per minute and, for thicker materials, it is able to form narrow, deep welds between square parts.

Laser welding machines are widely used in metal welding. Compared to conventional welding solutions, the running costs are low and the weld surface is smooth.

Advantages

High-precision connection even for small parts

Low heat input to minimize distortion

Non-contact welding – no degradation of weld quality

No current passing through the part

Welding of dissimilar metals (e.g. copper to aluminum)

Minimal maintenance – high tool availability

Easy automation for high productivity, high volume manufacturing

Applications

Sheet metal processing, rail transportation, automobiles, construction machinery, agricultural and forestry machinery, electrical appliance manufacturing, elevator manufacturing, household appliances, food machinery, textile machinery, tool processing, petroleum machinery, food machinery, kitchen and bathroom, decorative advertisement, laser external processing services