The laser jewelry repair machine is ideal for a variety of metal joining and repair applications in the jewelry industry. The system’s compact, portable, space-saving design ensures perfect repairs with the jewelry laser welding machine’s superior jewelry repair capabilities, whether it’s a ring, a delicate necklace, or a complex piece.

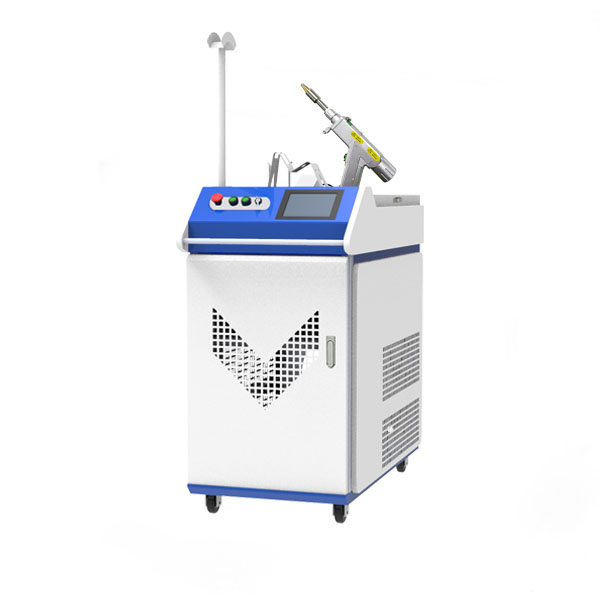

laser jewelry repair machine is a compact size and light-weight laser welding and repairing machine designed for the jewelry industry. It is equipped with a 200W Nd Yag laser and a high-resolution CCD monitor. It now become the most popular model for jewelry shops worldwide.

Laser Power: The 200W laser power ensures powerful and efficient repairs, providing the precision needed for delicate jewelry work.

Pulse Width Range: With a range of 1-20ms, the machine offers excellent control over the energy delivered, allowing for precise and controlled welding or cutting.

Max. Single Pulse Energy: The machine can deliver up to 50J of energy per pulse, offering high precision for spot welding and fine repairs without causing damage to surrounding areas.

Frequency Range: The frequency range of 1-50Hz allows for flexibility in different applications, from small repairs to larger, more complex tasks.

User-Friendly Interface:

Multilingual HMI Screen: The multilingual HMI (Human-Machine Interface) screen makes the machine accessible to jewelers around the world, ensuring easy operation and seamless communication.

Precision Positioning: Equipped with a 10X Microscope and CCD Monitor, the JW-M200 offers exceptional visibility and precision for the most detailed repair tasks, allowing jewelers to work with pinpoint accuracy.

Efficient Cooling System:

Air Cooling with Water Circulation: The cooling system uses air cooling with water circulation, ensuring the machine remains at optimal working temperatures during extended operations, improving longevity and performance.

Compact Design:

Dimensions: With compact dimensions of 680x360x363mm, the JW-M200 is designed to fit comfortably in any jewelry workshop without taking up too much space.

Jewelry Welding & Repair: Ideal for fixing broken pieces, resizing rings, and repairing delicate jewelry items such as bracelets, necklaces, and earrings.

Spot Welding: Perfect for spot welding small parts of jewelry, allowing for precise control without causing damage to gemstones or surrounding materials.

Resizing Rings & Settings: Excellent for resizing rings and adjusting settings with minimal heat impact, preserving the integrity of the jewelry.

Stone Insertion & Modification: Allows for setting or removing gemstones without harming the jewelry piece or the stones themselves.

Gold, Silver, Platinum, and More: Capable of working with a wide range of precious metals including gold, silver, platinum, and other alloys commonly used in jewelry crafting.