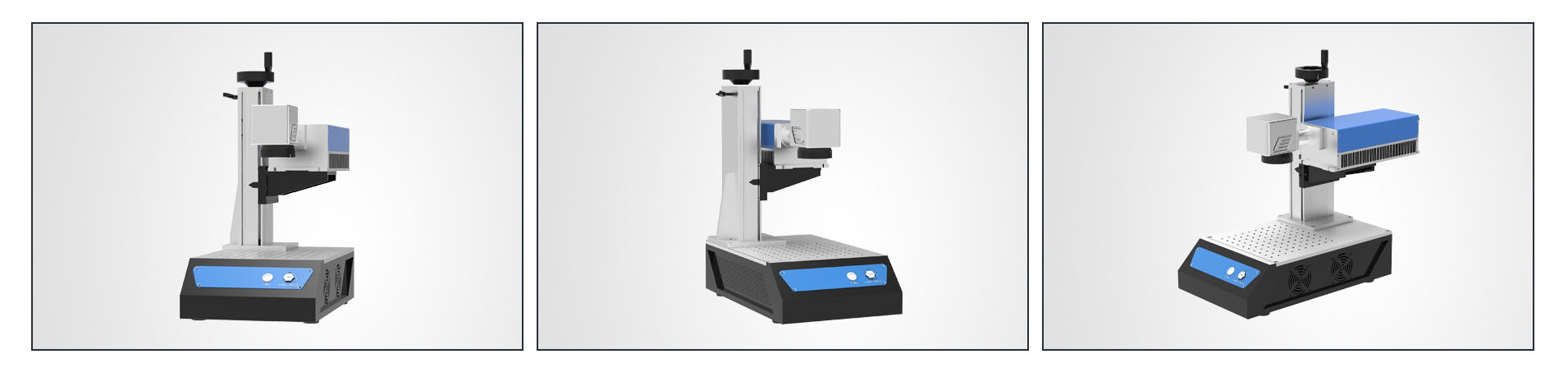

The MF-QS Mini Laser Marking Machine is a compact yet powerful solution for high-precision marking, engraving, and etching on a wide range of materials. Designed for industries such as electronics, automotive, jewelry, and consumer goods, this machine offers exceptional performance in a small footprint. With advanced laser technology, easy operation, and customizable features.

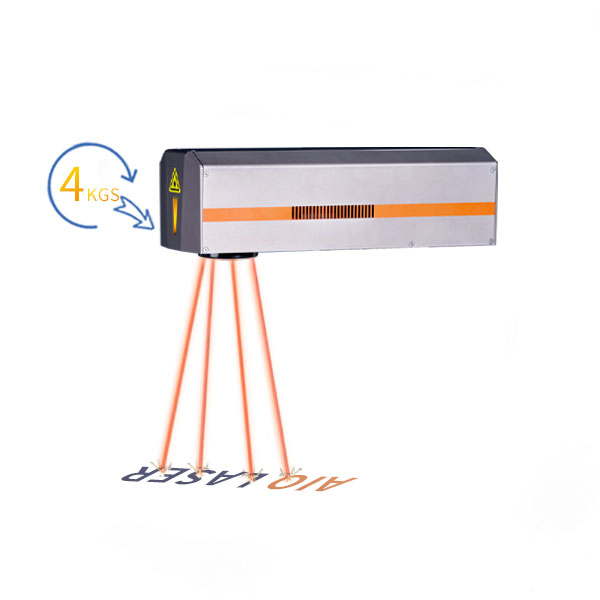

The portability of the mini laser marking machine opens up new possibilities for on-site and remote marking tasks. Its lightweight and compact design makes it easy to move around and ideal for marking large, complex objects or hard-to-reach areas. It is suitable for workshops, construction sites and industrial facilities.

Frequency Range: 30-60kHz frequency ensures high-speed marking with excellent precision.

Pulse Width: The 130ns pulse width delivers clean, sharp marks with minimal heat effect on materials, perfect for fine and intricate designs.

High Precision: Achieves ultra-fine engraving and marking with minimal heat input, ensuring high-quality, lasting results.

User-Friendly Operation:

Software: Operates with the intuitive EZCAD2.14.11-LITE software, allowing users to easily control marking parameters, designs, and layouts. This software supports a wide range of file formats for flexible design integration.

Controller: The FBLI-B-LV4 controller offers fast and reliable control of the marking process, ensuring smooth and consistent operation.

Flexible & Customizable:

Adjustable Z Lift Travel: Features 500mm of adjustable Z-lift travel, with an optional 700mm for added flexibility, making it easier to work with larger or varying heights of materials.

Efficient Cooling:

Air Cooling: The system uses an efficient air cooling method to keep the machine operating at optimal temperatures, ensuring long-term performance and reliability.

The mini laser marking machine utilizes advanced laser technology. It provides excellent marking quality with high precision and speed. It uses a focused laser beam. It leaves permanent, clear and precise marks on a wide range of materials such as metals, plastics, wood, rubber and more. Serial numbers, logos or barcodes or complex patterns can be engraved. This tool does it all and delivers excellent results every time.

Compact in size and lightweight in design, the 20W 30W MF Series of fiber optic laser markers is ideal for small businesses and hobbyists who want to mark or engrave on stainless steel, aluminum and other metals.

Equipped with a highly stable, high-speed, air-cooled laser source, 3W 5W UV,the MU Series excels at marking and engraving tasks on heat-sensitive materials. Ideal for high quality processing of glass, plastics and crystal