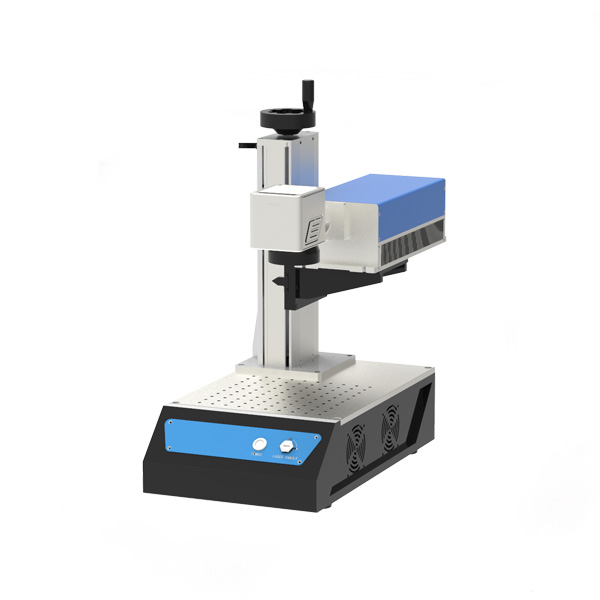

The MT350 series wafer laser trimming machine is designed for precise trimming of semiconductor wafers and is compatible with various sizes (4-inch, 6-inch, 8-inch, etc.). It features visual identification and positioning capabilities, allowing for full wafer preview and arbitrary positioning. The machine also includes data collection, yield statistics and determination, defective product marking, and automatic handling of wafer loading and unloading.

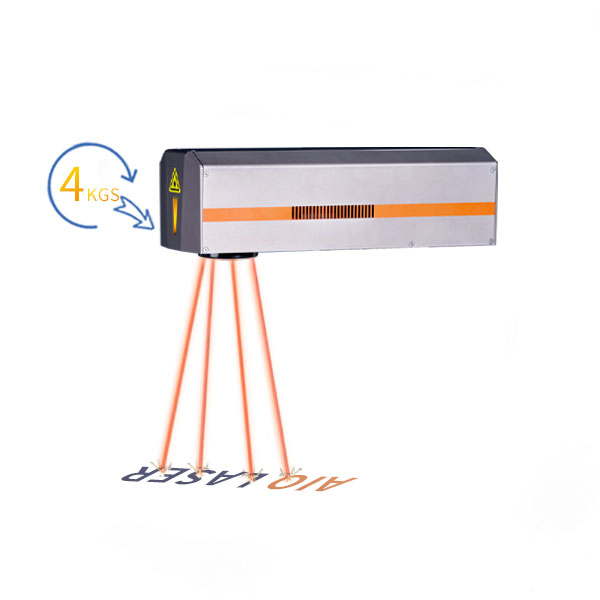

The equipment utilizes ultra-high precision modules and high-speed scanning galvanometers to enhance alignment accuracy and production efficiency. It operates with a 355 nm laser source (other types of laser sources can be customized) and has an independently developed control system that achieves a trimming accuracy of <±0.3%. Additionally, it is equipped with a GBIP expansion interface for connecting external measurement devices for further functionality expansion.

The software has independent intellectual property rights, featuring a user-friendly interface and simple operation;

It includes a wafer preview function;

Supports the import and export of schemes, facilitating the processing of different product models;

Supports processing data recording, meeting quality control data analysis needs; flexible and easy-to-use self-programming capabilities to meet personalized trimming requirements, allowing for easy saving, retrieval, and modification, significantly improving mass production efficiency;

The software can perform visual recognition, XY alignment, angle detection, and automatic focal length adjustment for the platform;

Supports distance and angle measurement functions;

Supports remote functionality, allowing integration with MES systems or collaboration with other equipment;

Equipped with coaxial vision alignment functionality, improving processing accuracy and operational convenience;

Equipped with paraxial vision functionality, supporting motorized zooming;

Automatic wafer handling mechanism for achieving automated production.