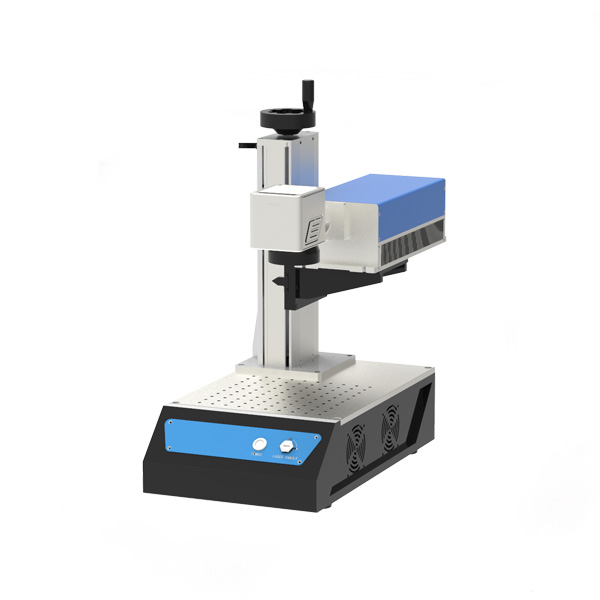

The RD-L500 Linear Displacement Potentiometer Tester is a high-precision integrated testing instrument launched for the potentiometer market, designed to test and measure various parameters of linear displacement potentiometers. The development of this device is based on relevant theoretical foundations such as GJB1865A-2015 Non-Wound Precision Potentiometer General Specification and GBT-15298-94. With the proprietary measurement software (DsmLab V1.0) developed in-house, it enables precise measurement of various technical parameters of linear displacement potentiometers, meeting the measurement needs of potentiometer production and quality control in military enterprises.

RD-L500: Professional Tester for Linear Displacement Potentiometers

Details

RD-L500: Tester for Linear Displacement Potentiometers

Specifications

● The equipment adopts a dual-station design, ergonomic operation, with a metal frame and an epoxy insulation board surface, providing convenient operation and significantly improving product testing efficiency (testing efficiency: <2 minutes per unit).

● The equipment uses a precision DD direct drive servo system, coupled with a high-precision 6-inch digital multimeter and a professional voltage (current) source, ensuring measurement accuracy and stability.

● It features a pneumatic limit and manual locking structure, with adjustable Z-axis in the clamping frame, compatible with testing products of different specifications and shaft diameters.

● The equipment has powerful functions, capable of testing all major technical indicators of potentiometers in one go (test items can be selected), with simple software operation and user-friendly interface.

● The equipment adopts a high-frequency sampling system (maximum sampling frequency: 5KHz), greatly increasing data collection frequency.

● Measurement data can be exported in real-time (exportable items can be selected), automatically generating test reports to meet the needs of raw data storage and recording.

● The equipment is capable of measuring products with different wiper modes, meeting the testing requirements for different products.