SLM Machine is used for industrial-grade additive production. We also provide industrial metal 3D printing with advanced processes, compatible with the widest range of metal materials, including aluminum alloys, titanium alloys, cobalt-chrome, nickel-based alloys, stainless steel, tool steel, copper alloys and other micro-grade metal powders.

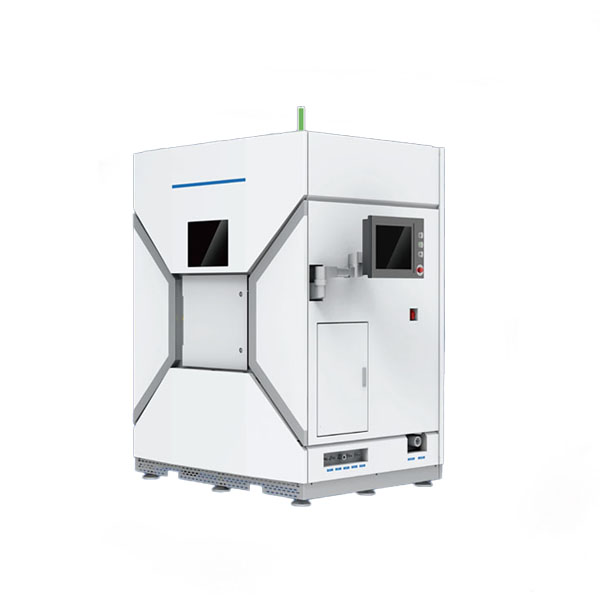

SLM DMLS Metal Powder 3D Laser Printing Machine

SLM Machine

SLM Printing Technology

SLM printing uses selective laser melting technology to melt metal powder and solidify it layer by layer until a three-dimensional part is built. During this process, a ruler in the build chamber will lay a layer of metal powder, and a high-powered laser will selectively melt the powder by tracing the cross-section of the part on the surface of the powder bed, and then apply a new coating of material for the next layer. The whole process is carried out in a high vacuum chamber or a chamber filled with protective gas to prevent the metal powder from reacting with oxygen at high temperatures.

Features

High surface quality of parts before polishing.

High part accuracy, suitable for precision samples.

Direct production of functional metal parts, simplifying the manufacturing process.

The parts have good metallurgical and mechanical properties, with a relative density greater than 99%, and no subsequent processing is required.

Depending on the size and complexity, parts can be printed in minutes to hours.

Direct production of functional complex geometric parts, such as snap-on or loose hinges

Depending on the complexity, parts can be completed in minutes or hours.

Wide selection of materials, metal powder can be a single metal or an alloy.

Especially suitable for single or small number of functional parts.

Application

Automotive/Aerospace/Industrial/Jewelry and Watches/Footwear/Sports Equipment/Medical/Tools/Rapid Prototyping

Specifications

| Model | SLM-120 | SLM-260 | |

| Laser | Laser Type | CW Fiber | CW Fiber |

| Wavelength | 1064nm | 1064nm | |

| Laser Power | 200W/500W | 500W | |

| Scanning System | Brand | SCANLAB | SCANLAB |

| Max. Scanning Speed | 6m/s | 6m/s | |

| Control System | O/S | Win10 | Win10 |

| Slicing Software | Materialise (Not Included) | Materialise (Not Included) | |

| Operating Software | JCZ-3DP Multilingual | JCZ-3DP Multilingual | |

| 3D File Format | STL(3D File), SLC/SLI(Sliced File) | STL(3D File), SLC/SLI(Sliced File) | |

| Coating System | Coating Thickness | 0.02-0.1mm | 0.02-0.1mm |

| Motion Control | Axis Accuracy | ±5um | ±5um |

| Prototypicality | Precision | ±0.1mm per 100mm | ±0.1mm per 100mm |

| Material | Stainless Steel, Titanium Alloy, Aluminum Alloy, Die Steel, Cobalt Chrome Alloy, Nickel Base Alloy | ||

| Max. Prototyping Size | 120x120x150mm | 260x260x320mm | |

| Max. Prototyping Speed | 2-20cm³ per Hour | 2-20cm³ per Hour | |

| Others | Power Supply | 380V | 380V |

| Dimension | WDH 1532×1390×1830mm | WDH 2925x1056x2135mm | |