SLS printing, or selective laser sintering, is an additive manufacturing process that uses a laser to sinter or bond powdered materials together.

The SLS 3D printer utilizes a high-power CO2 laser to selectively sinter powder materials, enabling the creation of perfect parts or models with high-quality surfaces and hardness.

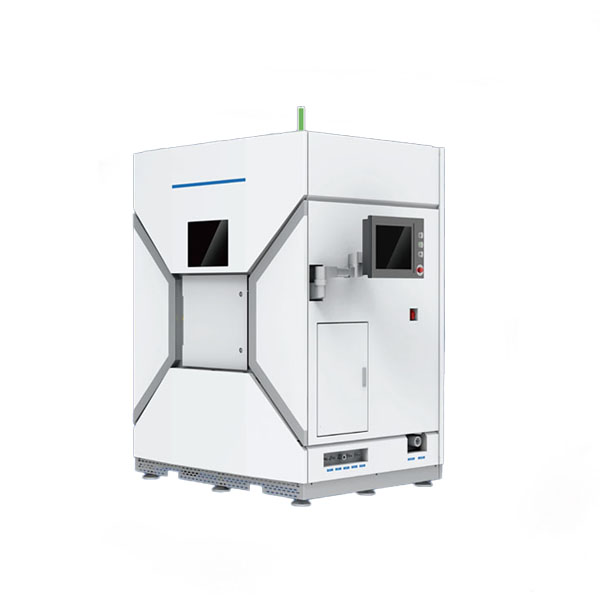

Compact, closed system

Negative pressure system keeps powder inside while enabling open access and easy cleanup.

Automatic powder mixing

New and old powders are automatically dispensed and mixed so you can reduce waste and control your powder supply.

Less material waste

A 30% material refresh rate means you can print indefinitely with up to 70% recycled powder. The machine’s sieve filters out particles, which are then remixed with new powder and reused for future prints.

Uninterrupted printing

Reduce downtime with an uninterrupted, cycled workflow enabled by transfer of modular build chambers and powder cartridges.