Laser cleaning technology has transformed the way industries approach surface preparation and rust removal. With the ability to effectively eliminate contaminants without damaging the underlying material, laser cleaning machines are becoming essential tools in various applications. This article explores different types of laser cleaning machines, their uses, and their advantages.

What is Laser Cleaning?

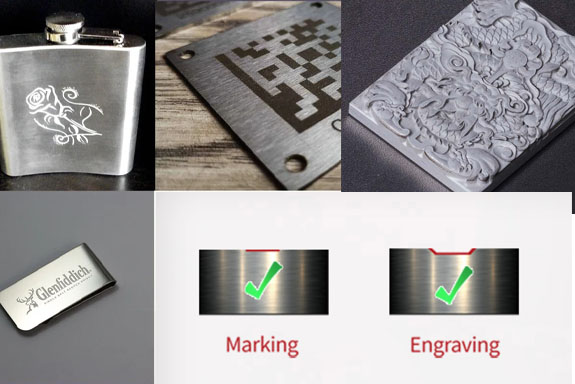

Laser cleaning is a non-contact process that utilizes a focused laser beam to remove rust, paint, grease, and other contaminants from surfaces. The high energy of the laser vaporizes or ablates the unwanted material while leaving the substrate intact. This method is not only efficient but also environmentally friendly, as it typically requires no chemicals or abrasive materials.

Types of Laser Cleaning Machines

1. Rust Cleaning Machines

Rust cleaning machines are specifically designed to remove rust from metal surfaces. These machines employ high-powered lasers that effectively vaporize rust without damaging the underlying metal. They are ideal for applications in industries such as automotive, shipbuilding, and metal fabrication, where maintaining the integrity of the base material is crucial.

2. Laser Cleaning Machines for Wood

Laser cleaning machines for wood are specialized systems that can effectively remove coatings, stains, and contaminants from wooden surfaces. These machines utilize lower power settings to ensure that the wood is not damaged during the cleaning process. This makes them perfect for restoration projects or for preparing wood surfaces for further finishing.

3. Laser Cleaning Machines for Rust Removal

Laser cleaning machines for rust removal combine powerful laser technology with precision to remove rust from various metal surfaces. These machines can be used for large-scale industrial applications or smaller operations, depending on the model. They significantly reduce the time and labor involved in traditional rust removal methods.

4. Industrial Laser Cleaning Machines

Industrial laser cleaning machines are built for high-volume applications where efficiency and effectiveness are paramount. These machines often feature higher power outputs (like 1000W or 2000W) to handle heavy-duty cleaning tasks. They are commonly used in manufacturing facilities, shipyards, and other industrial settings.

5. Handheld Cleaning Lasers

Handheld cleaning lasers offer a portable and flexible solution for rust removal and surface cleaning. These devices are lightweight and easy to maneuver, making them ideal for small jobs or areas that are difficult to access. Handheld lasers can be effective for spot cleaning or detailed work on smaller surfaces.

6. Backpack Laser Cleaning Machines

Backpack laser cleaning machines are innovative solutions that allow operators to move freely while cleaning surfaces. These machines are worn like a backpack and are particularly useful for outdoor cleaning or in spaces where mobility is essential. They combine portability with the power needed for effective cleaning.

7. Fiber Laser Rust Removers

Fiber laser rust removers utilize fiber laser technology to achieve precise and efficient rust removal. These machines are known for their speed and effectiveness, making them suitable for both industrial and smaller-scale applications. Fiber lasers are particularly effective on various metals, providing consistent results.

Advantages of Laser Cleaning

- Environmentally Friendly: Laser cleaning reduces the need for harsh chemicals or abrasives, making it a cleaner and safer option for both operators and the environment.

- Precision: The focused nature of laser beams allows for accurate cleaning without damaging the substrate, ensuring that even delicate surfaces can be treated.

- Efficiency: Laser cleaning is a fast process, often requiring less time than traditional methods, which can lead to reduced downtime in industrial settings.

- Versatility: Laser cleaning machines can be used on various materials, including metal, wood, and plastics, making them suitable for a wide range of applications.

- Cost-Effectiveness: While the initial investment in laser cleaning technology may be higher than traditional methods, the long-term savings in labor, materials, and maintenance can make it a cost-effective solution.

Conclusion

Laser cleaning machines are transforming the way industries approach rust removal and surface preparation. With their precision, efficiency, and environmentally friendly operation, these machines are becoming essential tools across various sectors. Whether you need a portable solution or a powerful industrial machine, the advancements in laser cleaning technology offer effective options for maintaining and restoring surfaces.

由用户投稿整理稿件发布,不代表本站观点及观点,进行交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。