3D printing technology has evolved significantly over the years, leading to the development of various methods and machines that cater to different applications. Among these, powder 3D printers and Selective Laser Melting (SLM) printing have gained prominence in industries such as aerospace, automotive, and jewelry making. This article explores the workings of powder 3D printers, the SLM process, and their applications in modern manufacturing.

What is Powder 3D Printing?

Powder 3D printing refers to a category of additive manufacturing processes that use powdered materials to create objects layer by layer. This method allows for intricate designs and complex geometries that are often impossible to achieve with traditional manufacturing techniques. Powder 3D printers are widely used for metals, ceramics, and plastics, making them versatile tools in various industries.

Selective Laser Melting (SLM)

SLM printing is a specific type of powder 3D printing that utilizes a high-powered laser to melt and fuse metal powders together. The process begins with a thin layer of metal powder being spread across a build platform. A laser then scans the surface, melting the powder in specific areas to create the desired shape. Once the layer is completed, the platform lowers, and another layer of powder is applied. This process repeats until the part is fully constructed.

Advantages of SLM Printing

- Complex Geometries: SLM allows for the creation of complex structures that traditional manufacturing methods may struggle with. This includes intricate internal channels and lattice structures.

- Material Efficiency: Since the process uses only the material needed for the part, it minimizes waste compared to subtractive manufacturing techniques.

- Customization: SLM is ideal for producing custom parts tailored to specific applications, making it popular in industries like aerospace and medical devices.

Applications of Powder 3D Printers and SLM

1. Jewelry 3D Printers

Jewelry 3D printers often utilize SLM technology to create intricate and high-quality pieces. The ability to produce complex designs allows jewelers to innovate and reduce production times significantly. Fine details can be replicated with high precision, ensuring that the final products meet the high standards of the jewelry industry.

2. Metal Printer Machines

Metal printer machines, particularly those employing SLM technology, are essential in sectors where metal components are critical. These machines are capable of printing parts in stainless steel, titanium, and other alloys, providing strong and lightweight components for various applications.

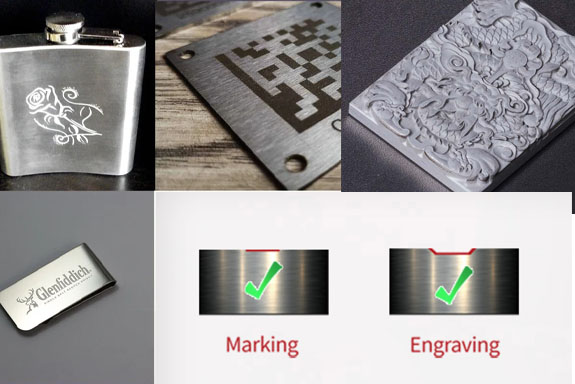

3. Combination Machines: 3D Printer and Laser Engraver

Machines that combine a 3D printer and laser engraver offer versatility in manufacturing. These systems can produce 3D objects while simultaneously engraving intricate designs or text onto the surfaces. This is particularly useful in custom jewelry production, where unique engravings can enhance the value of a piece.

4. Liquid 3D Printers

Liquid 3D printers utilize photopolymerization techniques to create parts from liquid resins. This method differs from powder printing but can complement it by providing high-resolution details that might be required in certain applications.

5. Stainless Steel 3D Printers

Stainless steel 3D printers are a crucial asset for industries requiring strong, corrosion-resistant materials. SLM technology excels in this area, enabling the production of durable stainless steel components for automotive and aerospace applications.

3D Printing Machine Prices

The price of 3D printing machines can vary widely depending on their capabilities and technologies. Entry-level printers may cost a few thousand dollars, while industrial-grade powder 3D printers and SLM machines can range from tens of thousands to over a million dollars, depending on their features and specifications. Businesses must weigh their production needs against the investment to determine the right machine for their operations.

Conclusion

Powder 3D printing and SLM technology are at the forefront of modern manufacturing, enabling the production of complex, high-quality parts across various industries. From jewelry making to aerospace applications, the ability to create intricate designs with precision and efficiency is revolutionizing how products are manufactured. As technology continues to advance, the possibilities for 3D printing will expand even further.

由用户投稿整理稿件发布,不代表本站观点及观点,进行交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。